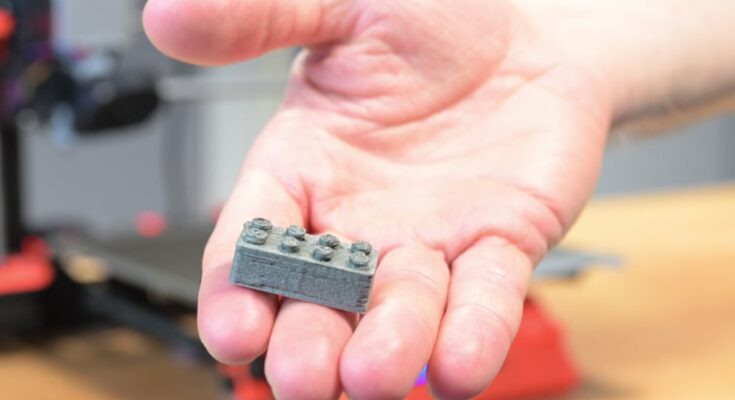

The European Space Agency has developed a new kind of building block, similar to Lego bricks, using 3D printing technology. These space bricks are made from dust that comes from a meteorite found in northwest Africa in 2000.

This meteorite is about 4.5 billion years old. The dust from this meteorite serves as a substitute for lunar soil, which covers the moon’s surface and is mainly formed by the impact of meteorites. The ESA is exploring ways to build structures in space using these innovative bricks.

In-Situ Resource Utilization (ISRU)

In the field of space exploration, this practice is termed In-Situ Resource Utilization (ISRU) and is the main focus of the ESA’s Spaceship EAC team, located in Cologne, Germany.

Aidan Cowley, a science officer at ESA who leads the team, expressed the team’s passion for innovative construction. It conceived of the idea of shaping space dust into small blocks resembling Lego bricks so as to experiment with various construction methods.

Future Moon bases.

European Space Agency @esa developed a LEGO-style space bricks using dust made from a meteorite. The meteorite discovered in Northwest Africa in 2000 was 4.5 billion years old and had space materials like metal grains and chondrules, ideal components to… pic.twitter.com/5sZyE0St7s— Maurizio Iβλἄ (@Dragonmaurizio) July 3, 2024

“Our teams are working towards the future of space travel and take inspiration from not just what’s above us, but also what we can find on Earth,” said Cowley. “No one has ever built a structure on the moon, so we have to work out not only how we build them but what we build them out of as we can’t take any materials with us.”

Grinding and mixing of meteorite pieces

The team processed pieces of meteorite into fine dust to create a material suitable for 3D printing. They mixed this dust with a small amount of polylactic acid, a type of eco-friendly bioplastic, and a “regolith simulant” made of Earth minerals that mimic the lunar surface.

Their goal was to replicate the shape and size of Lego bricks, but achieving this precision on such a small scale with 3D printing was challenging and required extensive adjustments, as noted by the ESA. The team mentioned that using Lego brick shapes has become a standard test for projects like theirs due to these challenges.

The blocks function similarly to Lego bricks, whereby tubes underneath interlock with studs on top, creating a strong connection known as “clutch power,” famous for keeping Lego bricks firmly connected.

“The result is amazing and whilst the bricks may look a little rougher than usual, importantly the clutch power still works, enabling us to play and test our designs,” said Cowley. “It was both fun and useful in scientifically understanding the boundaries of these techniques.”

The Lego Group has placed 15 of the ESA’s space bricks on exhibit at its stores worldwide, aiming to encourage children to create their own space shelters.