Scientists developed an electricity-generating fabric that turns clothes into wearable chargers, powering devices through body heat. Imagine wearing a sweater that monitors your health or even charges your phone during a run, all powered by an electricity-generating silk textile.

Creating such clothing has been difficult because it’s hard to find materials that work well with fabrics and can also carry electricity safely. But now, researchers at Sweden’s Chalmers University of Technology have found a solution.

They’ve coated regular silk thread with a special plastic that can carry electricity. This discovery may help make clothing that can produce power on its own.

Thermoelectric textiles create electricity from temperature differences, like the warmth from our bodies compared to cooler air.

This technology could be very useful in daily life. When paired with sensors, these fabrics can power devices without needing batteries. These sensors could help track our movements or measure our heartbeat, offering new ways to monitor health and fitness.

For these textiles to work effectively, they need to be worn close to the skin, which means the materials must be both safe and flexible. The silk thread used in this research is coated with a special plastic that can conduct electricity, making it a good match for fabric.

This plastic, known as a conducting polymer, is designed to be bendable, lightweight, and usable in both liquid and solid forms. Importantly, it is also non-toxic, ensuring it is safe for wear. The research was recently published in the journal Advanced Science.

Carbon-based thread for conducting electricity

To improve conductivity and durability, researchers designed a new thread using carbon-based materials instead of traditional metals. This innovation enhances stability and improves the thread’s ability to conduct electricity, making it ideal for powering wearable electronics

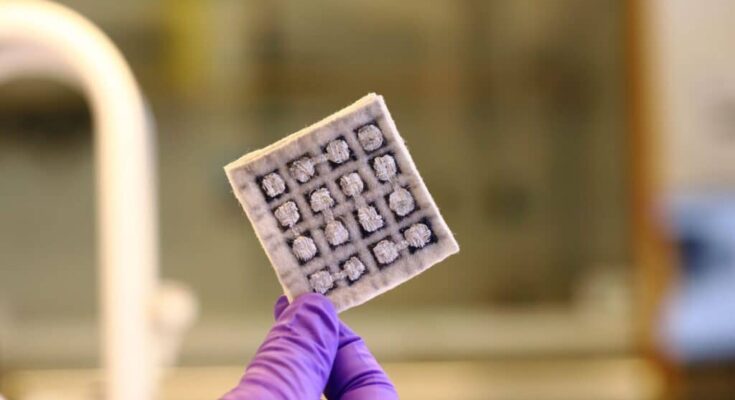

To demonstrate its practical use, the team created two simple thermoelectric generators: a button sewn with the thread and a piece of fabric with threads stitched into it.

When they placed these textiles between hot and cold surfaces, the voltage rose. The effect varied based on the temperature difference and the amount of conductive thread in the fabric, proving the concept for real-world applications.

For example, the larger fabric sample generated around 6 millivolts with a 30-degree Celsius temperature difference. With a voltage converter, it could theoretically charge small electronics through a USB connection. The thread has proven durable, retaining its performance for at least a year and can even withstand machine washing.

Currently, creating this thermoelectric fabric is labor-intensive and only feasible in a lab. Each piece must be handmade, taking up to four days just to sew the thread into the fabric. Despite these challenges, researchers are optimistic. They believe that, with further development, the process could be automated and scaled up for broader production.